Product Description

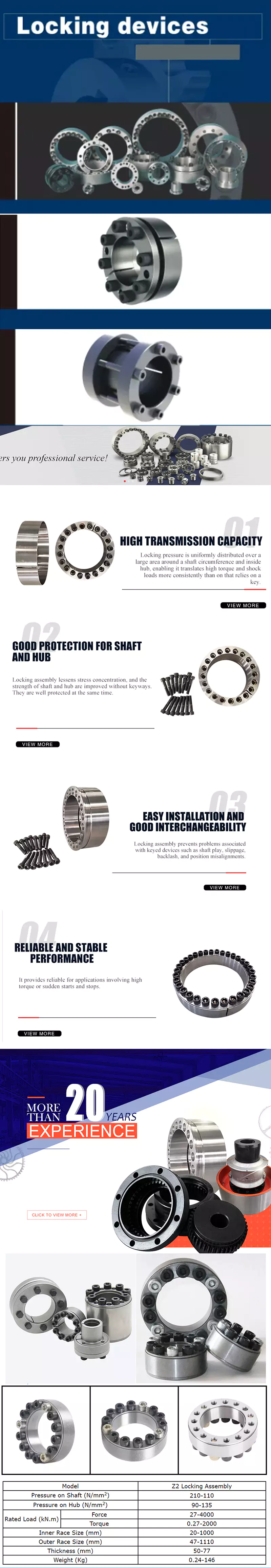

CZPT Keyless Locking Units are used in rotating machinery, making clamping pressure amongst area of locking gadget and shaft to produce adjustable and releasable mechanical relationship, so as to clamp gears, pulleys and other factors to a shaft without threads or keys.

Raw resources accessible in:

l Metal C45E,

l Metal 42CrMo4V

l Stainless Steel AISI431,

l Stainless Metal AISI304

Attributes:

1. Join hubs solidly to shafts

2. Easy set up and disassembly

three. Substantial torque transmission

4. Prolonged life time and easy upkeep

five. Minimal notching effect

6. Reduction of use and tear of expensive equipment elements

Ubet Machinery provides kinds of Keyless Locking Products, which are interchangeable with numerous European and American brands. Large good quality always will come the very first.

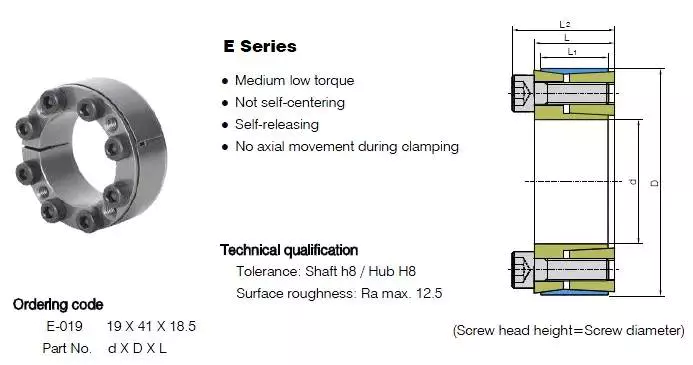

Ubet Keyless Locking System KLD-1 Medium torque, not self-centering, Medium surface area pressures, No axial hub motion, flexible use, machining tolerance shaft H8, hub H8 socket head locking screw DIN912-twelve.9. The most common sort of all KLD Locking System, Equipment Wheel Connection the slotted design and style of the double tapered rings permits fairly substantial mounting tolerance, The large taper angles are not self-locking and facilitate the release of the relationship.

KLD-1 Interchange with Z2,BIKON 4000,BEA BK40,BONFIX CCE2000,Obstacle 01,Chiaravalli RCK40,CONEX A, Fenlock FLK200,ITALBLOCK CN210,KTR100,KINLOK LOK30,KBS40,KANA 200,MAV 2005,POGGI CAL-A,RFN7012,Ringspann RLK200,Ringblok 1120,SIT 1,SATI KLGG,TOLLOK TLK200,Tsubaki AS,TAS3571,V-Blok VK400,Walther Flender MLC 1000,Fenner Drive B-Loc B400,LoveJoy SLD1500, FX10,OKBS40,DRIVELOCK40

Ubet Keyless Locking Assembly KLD-two Medium torque, self-centering, small cross area, machining tolerance shaft H8, hub H8 Socket head locking screw DIN912-twelve.nine

Self-centering with superb concentricity the small outer diameter is area-saving and suitable for modest wheel diameters the spacer ring amongst the outer flange and the hub maintains the fitting placement in the axial direction to enable actual positioning without having a shaft collar the drive-off threads in the outer flanges are used for dismantling.

KLD-2 Interchange with Z11,BIKON 8000,BEA BK80,BONFIX CCE1000,Problem 02,Chiaravalli RCK80,CONEX B,7110 ECOLOC, Fenlock FLK110,GERWAH PSV2571.1,ITALBLOCK CN55,KTR250,KINLOK LOK10,KBS80,MAV 5061,POGGI CAL-B,RFN7110,Ringspann RLK110,Ringblok 1100,SIT 3,SATI KLCC,TOLLOK TLK110,Tsubaki TF,V-Blok VB800B,Walther Flender MLC3000,Fenner Drive B-Loc B800,LoveJoy SLD1900, FX20,OKBS80,DRIVELOCK80

Ubet Locking Aspects KLD-3

Minimal torque, Medium area strain, Taper rings only, Minimal axial and radial proportions

This clamping set is self-centering with exceptional concentricity. The incredibly modest outer diameter is room-preserving and appropriate for little wheel diameters. The spacer ring among the outer flange and the hub maintains the fitting position in the axial course to allow specific positioning without a shaft collar. The thrust-off threads in the outer flanges are employed for dismantling.

KLD-3 Interchange with Z1,BIKON 5000,BEA BK50,BONFIX CCE3000,Problem 03 Chiaravalli RCK50,CONEX C,Fenlock FLK300,ITALBLOCK CN31,KRT150,KINLOK LOK80,KBS50,KANA 300,MAV 3003,POGGI CAL-C,RFN8006,Ringspann RLK300,Ringblok 1060,SIT 2,SATI KLNN,TOLLOK TLK300,Tsubaki EL, ,Walther Flender MLC 2000,Fenner Drive B-Loc B112,LoveJoy SLD350, FX30,OKBS50,DRIVELOCK50

Ubet Mechanical Locking Device KLD-four

Large torque, self-centering, medium area pressure, machining tolerance shaft H8, hub H8 socket head Locking screw DIN912-twelve.9

KLD-4 Interchange with Z3,BIKON 7000A,BEA BK70,BONFIX CCE4000,Challenge 04,Chiaravalli RCK70,CONEX D,7004 ECOLOC, Fenlock FLK130,GERWAH PSV2007,ITALBLOCK CN54/N,KTR200,KINLOK LOK20A,KBS70,MAV 6901,POGGI CAL-D,RFN7013.,Ringspann RLK130,Ringblok 1300.1,SIT 5A,SATI KLDA,TOLLOK TLK130,V-Blok VK700, FX40,OKBS70,DRIVELOCK70

Ubet Shaft Hub Link KLD-5

Medium torque, diminished duration, medium self-centering, Large area force, machining tolerance shaft H8, hub H8 socket head Locking screw DIN912-twelve.nine

Suited for slim, disk-shaped wheel hubs. Self-centering and self-locking in the clamping state.

KLD-5 Interchange with Z3B,BIKON 1003,BEA BK13,BONFIX CCE4100,Obstacle 05,Chiaravalli RCK13,CONEX DS,7003 ECOLOC, Fenlock FLK132,GERWAH PSV2006,KTR203,KBS13,KANA 201,MAV 1062,POGGI CAL-DS,RFN7013., Ringspann RLK132,Ringblok 1710,SIT 6,SATI KLAA,TOLLOK TLK132,TAS3003, V-Blok VK160,Walther Flender MLC 5006,LoveJoy SLD1750, FX41, OKBS13, DRIVELOCK13.

Ubet Shaft Locking Gadget KLD-6

Medium torque, self-centering, Minimal surface strain, No axial hub motion, machining tolerance shaft H8, hub H8 socket head Locking screw DIN912-12.9

KLD-6 Interchange with Z13,BIKON 7000B,BEA BK71,BONFIX CCE4500,Obstacle 06,Chiaravalli RCK71,CONEX E,7007 ECOLOC, Fenlock FLK131,GERWAH PSV2007.3,ITALBLOCK CN54/S,KTR201,KINLOK LOK20B,KBS71,MAV 6902,POGGI CAL-E,RFN7013.1,Ringspann RLK131,Ringblok 1300.2,SIT 5B,SATI KLDB,TOLLOK TLK131,Tsubaki KE,V-Blok VK700.1,Walther Flender MLC5000B, FX50,OKBS71,DRIVELOCK71

Ubet Clamping Electricity Lock KLD-seven

Medium torque, reduced size, Large floor pressure, No axial hub movement, machining tolerance shaft H8, hub H8 socket head Locking screw DIN912-12.9 Simultaneous Connection of Chain Sprocket

KLD-7 Interchange with Z8,BIKON 1006,BEA BK16,BONFIX CCE4600,Obstacle 07,Chiaravalli RCK16,CONEX ES,7006 ECOLOC,Fenlock FLK133,GERWAH PSV2006.3,ITALBLOCK CN9/4,KTR206,KBS16,KANA 201,MAV 1061,POGGI CAL-ES,RFN7013.1,Ringspann RLK133,Ringblok 1720,SATI KLAB,TOLLOK TLK133,Tsubaki AE,TAS3006,V-Blok VK130,Walther Flender MLC 5007,LoveJoy SLD1750, FX51,OKBS16,DRIVELOCK16

Ubet Shrink Disc KLD-fourteen

Substantial torque, No axial hub motion, Large pace application, favored solution for coupling hub and hollow shaft gearbox, DIN931-10.9 screw Sensible-Lock Shrink Disc, Narrow Hub Connection for sprockets, join hollow and sound shafts frictionally and backlash-cost-free.

KLD-14 Interchange with Z7B,BEA BK19,BONFIX CCE8000,Problem fourteen,Chiaravalli RCK19,CONEX SD, Fenlock FLK603, ,KTR603,KBS19,MAV 2008,RFN4071,Ringspann RLK603,Ringblok 2200,SATI KLDD,TOLLOK TLK603, Tsubaki SL, ,Walther Flender MLC 9050,Fenner Travel B-Loc SD10,LoveJoy SLD900, FX190,OKBS19,DRIVELOCK19

Ubet Locking Assembly KLD-15

Substantial torque, self-centering, Minimal-medium area force, machining tolerance shaft H8, hub H8 socket head Locking screw DIN912-12.nine

KLD-15 Interchange with BEA BK15, Problem 15,Chiaravalli RCK15,CONEX EP, Fenlock FLK134,KBS15 ,MAV 3061,Ringspann RLK134,SATI KLBB,TOLLOK TLK134, FX52,DRIVELOCK15

Ubet Locking Bushes KLD-16

Medium torque, Decreased length, Medium self-centering, High area force, machining tolerance shaft H8, hub H8 socket head Locking screw DIN912-twelve.nine

KLD-16 Interchange with BONFIX CCE4900,Problem 16,CONEX L,KTR225,KBS52,SATI KLHH, FX120

Ubet Ball Bearing Adapter Sleeve KLD-17

Low torque, Brief Size, Not self-centering, Reduced surface pressure, machining tolerance shaft H8, hub H8

KLD-17 Interchange with BEA BK25, Obstacle seventeen, KBS51, SATI KLFC, FX80

Ubet Bearing Adapter Sleeve KLD-17.1

Lower-medium torque, self-centering, lower floor pressure, machining tolerance shaft H8, hub H8

KLD-seventeen.1 Interchange with Z19B, BEA BK26,Obstacle 21,Chiaravalli RCK55, Fenlock FLK250,KTR125,KBS55, POGGI CAL-L,Ringspann RLK250,Ringblok 1500, SATI KLFF,TOLLOK TLK250

Ubet Shaft Clamping Collar KLD-eighteen

Low-medium torque, Brief Size, self-centering, minimal floor pressure, machining tolerance shaft H8, hub H8, socket head Locking screw DIN912-12.nine

This clamping set is self-centering and suitable for incredibly little shaft diameters. It transfers common to huge torques

KLD-18 Interchange with BEA BK61,Chiaravalli RCK61,7002 ECOLOC ,GERWAH PSV2061,KTR105,KBS61,MAV 7903,SATI KLSS, Walther Flender MLC 5050, FX350,OKBS61,DRIVELOCK61

Ubet Clamping System KLD-19

very large torque, self-centering, medium floor strain, no axial hub motion, machining tolerance shaft H8, hub H8, socket head Locking screw DIN912-12.9

This clamping set is self-centering with superb concentricity. The extremely small outer diameter is area-preserving and suitable for small wheel diameters. The spacer ring in between the outer flange and the hub maintains the fitting place in the axial route to allow exact positioning with out a shaft collar.

KLD-19 Interchange with Z12A,BIKON 1012,BEA BK11,BONFIX CCE9500,Challenge 19,Chiaravalli RCK11,CONEX F,7005 ECOLOC,Fenlock FLK400,GERWAH PSV2005,ITALBLOCK CN911,KTR400,KINLOK LOK40,KBS11,MAV 4061,POGGI CAL-F,RFN7015,Ringspann RLK400,Ringblok 1800,SIT 4,SATI KLEE,TOLLOK TLK400,Tsubaki Ad,TAS3012,V-Blok VK112,Walther Flender MLC 4000/MLC 7000,Fenner Push B-Loc B112,LoveJoy SLD2600, FX60,OKBS11,DRIVELOCK11

Locking System KLD-33 interchange with Z4, RFN7014

Locking Device KLD-34 interchange with Z5,BIKON 1015./1015.1, 7009 ECOLOC,Fenlock ,GERWAH PSV2009, KTR401,MAV 1008,RFN7015.,Ringspann RLK401,Ringblok 1810,TOLLOK TLK451,TAS3015./3015.1,

Keyless Locking System also phone as underneath

one. Welle-Nabe-Verbindungen

two. Wellenspannsaetze,

3. Spannsaetze,

4. Taper Spannbuchsen,

5. Taper Lock,

six. Keyless Locking Unit,

7. Keyless Locking Assembly,

eight. Keyless Shaft Locking Device,

nine. Keyless Shaft Hub Locking Device,

10. Keyless Bushings,

eleven. Keyless Shaft Hub Relationship,

twelve. Clamping Sleeve,

13. Clamping Component,

fourteen. Clamping Collar,

15. Clamping Bush,

16. Clamping Products,

seventeen. Clamping Established,

18. Clamping Electrical power Lock,

19. Cone Clamping Element,

twenty. Shaft Clamping,

21. Shaft Fixing,

22. Shaft Fixing Cone Clamping Element,

23. Conical clamping rings,

24. Shaft Lock Clamping Component,

twenty five. Shaft Clamping Element,

26. Shaft Clamping Collar,

27. Shaft Locking Device,

28. Shaft Hub Link,

29. Shaft Hub Locking Device,

thirty. Shaft Hub Locking Assembly,

31. Shaft Lock,

32. Silted Clamping Aspect,

33. Shaftlock Clamping Element,

34. Locking Assembly,

35. Locking Bushes,

36. Locking Rings,

37. Rigid Shaft Coupling,

38. Rigid Shaft Coupler,

39. Rigid Ring Block,

40. Ring Shaft Lock,

41. Ringblock Locking Assemblies,

42. Equipment Wheel Connection,

43. Zinc Plated Locking Gadgets,

44. Nickel Plated Locking Assembly,

forty five. Mechanical Locking Unit,

forty six. Mechanical shaft lock,

forty seven. Schrumpfscheibe,

48. External Locking Assembly,

forty nine. Slim Hub Link for Sprockets,

50. Shrink Disc,

fifty one. Brake Disc,

fifty two. Shrink Disk,

53. External Locking Assembly Light Responsibility,

54. Shrink Discs Normal Obligation,

fifty five. Shrink Disks Weighty Obligation,

fifty six. Smart-Lock Schrumpfscheibe,

57. Sensible-Lock Shrink Disc,

fifty eight. Bearing Adapter Sleeve,

59. Lock Nut,

sixty. Electricity NUT,

sixty one. Electrical power Website link,

62. Shaft Self-Lock Ring Nut,

63. Nickel Plated Locking Devices,

64. Zinc Plated Locking products,

65. Stainless Metal Locking Products.

|

US $2.5 / Piece | |

6 Pieces (Min. Order) |

###

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | Cold-Resistant, Corrosion-Resistant, Wear-Resistant, High Temperature-Resistance |

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Motorcycle, Food Machinery, Marine, Mining Equipment, Agricultural Machinery |

| Surface Treatment: | Zinc Plating |

| Material: | Carbon Steel |

| Rfn7015.0: | 100X145 |

###

| Samples: |

US$ 2.5/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

|

US $2.5 / Piece | |

6 Pieces (Min. Order) |

###

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | Cold-Resistant, Corrosion-Resistant, Wear-Resistant, High Temperature-Resistance |

| Application: | Textile Machinery, Garment Machinery, Conveyer Equipment, Packaging Machinery, Motorcycle, Food Machinery, Marine, Mining Equipment, Agricultural Machinery |

| Surface Treatment: | Zinc Plating |

| Material: | Carbon Steel |

| Rfn7015.0: | 100X145 |

###

| Samples: |

US$ 2.5/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

Available

|

|---|

Using a Power Lock

Using a power lock in your vehicle allows you to lock the doors without having to take your hands off the wheel. It is also great for front passengers to use.

Actuator

Among the most common features on any vehicle are power door locks. These locks work by turning a gear mechanism and lock or unlock the door. The gear mechanism is made of an electric motor and spur gears.

Power door lock actuators are critical to the operation of a power door lock feature. When a power door lock actuator fails, it disables the power door lock feature.

The most common complaint about a power door lock actuator is that it locks and unlocks intermittently. This may be due to a problem with the wiring or circuits.

Some symptoms of a faulty power door lock actuator are noises coming from inside the door. For example, when a motor is not turning, it will make a loud “clunk” sound. When a motor is working properly, there will be little or no noise.

A faulty power door lock actuator may also cause a car to lock and unlock randomly. This can happen due to a faulty circuit or circuits wearing out.

Alternatively, a faulty actuator may be the result of a water leak in the door. If this is the case, the water may enter the door lock actuator and cause it to malfunction. Fortunately, there are a number of ways to check the condition of your actuator and fix any problems.

Body controller

Almost all modern day cars have some form of power lock, but only a select few have a body controller to boot. The fancy name is the electronic control unit, but the acronym ECU stands for Electronic Control Unit, or ECU for short. The ECU is responsible for coordinating the myriad electronic components that are dotted throughout your vehicle’s occupant compartment. It also controls things like power windows and the air conditioning. You can see the ECU in action by glancing at your dashboard. It’s a small and power-packed box, but a discerning eye will spot a few stragglers amongst the more mundane tasks. The ECU is also responsible for ensuring the safety of passengers by ensuring that the doors remain unlocked until a specified interval.

The ECU’s lesser known cousins, like the power door lock, are only responsible for a few of the more mundane tasks. Aside from the usual suspects, the ECU also manages the power mirrors and the power windows, albeit on a less than optimal schedule. A faulty ECU isn’t quite as funky as it sounds, and can be rectified by a trip to the local mechanic. If you’re not a mechanic, you’ll likely be able to remedy the situation with a simple door lock replacement.

Check for broken wires

Occasionally, you will need to check for broken wires when using a power lock. Having a broken wire will require you to repair it, or replace it with a new one. However, this process can be quite difficult, as it is hard to reach the motor. If you are unsure what wires are connected to your vehicle, you should consult a wiring diagram. If you do not have a diagram, you can also use a multimeter to check for continuity across all wires. However, a multimeter is not enough to check for broken wires. You will also need rubber gloves to do this safely.

To check for broken wires, first make sure you have access to the wires that are in the lock motor. These are usually located near the plug on the door frame. If you can’t reach them, you can use jumper wires to connect the actuator to the 12 volt power supply and test it for power. If this does not work, you will need to remove the lock motor from its electronic control board and check for a broken wire harness. However, if this is not possible, you can use a Power Probe to apply 12 volts to the actuator.

editor by czh 2023-03-23