Solution Description

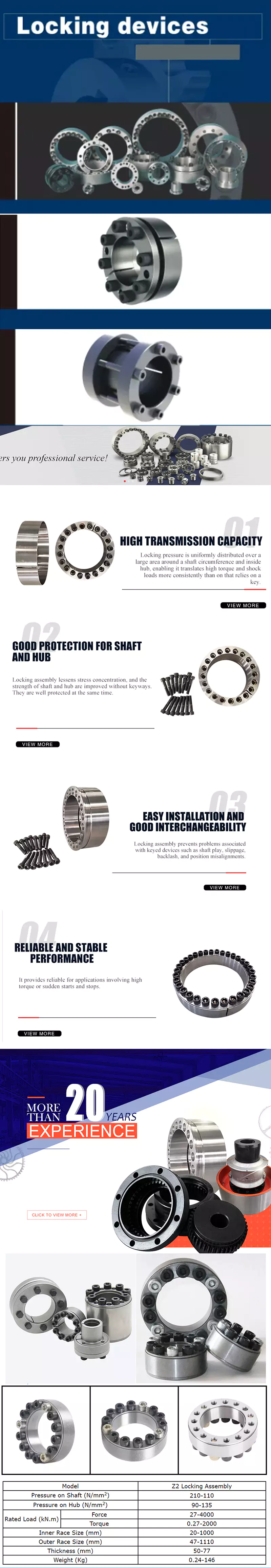

Description of Z7A Locking Device

The primary objective of the growth sleeve is to replace the purpose of splines and one keys, so as to realize the connection between the components (this kind of as gears, flywheels, pulleys, and so forth.) and the shaft to transmit the load.

When it is employed, via the action of large-toughness bolts, a huge keeping pressure is produced among the interior ring and the shaft, and in between the outer ring and the hub. When below load, torque, axial power, or the blended load of the 2 is transmitted by the blended stress of the growth sleeve and the components and the accompanying frictional pressure.

Parameter of Z7A Locking Device

|

US $5-35 / Set | |

1 Set (Min. Order) |

###

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Packaging Machinery, Motorcycle, Food Machinery, Mining Equipment, Agricultural Machinery |

| Material: | Bearing Steel |

| Product Name: | Z7a-250X460 Locking Assembly |

| Type: | Z7a-250X460 |

| Inner Size(mm): | 250 |

###

| Customization: |

Available

|

|---|

|

US $5-35 / Set | |

1 Set (Min. Order) |

###

| Standard or Nonstandard: | Standard |

|---|---|

| Application: | Textile Machinery, Garment Machinery, Packaging Machinery, Motorcycle, Food Machinery, Mining Equipment, Agricultural Machinery |

| Material: | Bearing Steel |

| Product Name: | Z7a-250X460 Locking Assembly |

| Type: | Z7a-250X460 |

| Inner Size(mm): | 250 |

###

| Customization: |

Available

|

|---|

Using a Power Lock

Using a power lock in your vehicle allows you to lock the doors without having to take your hands off the wheel. It is also great for front passengers to use.

Actuator

Among the most common features on any vehicle are power door locks. These locks work by turning a gear mechanism and lock or unlock the door. The gear mechanism is made of an electric motor and spur gears.

Power door lock actuators are critical to the operation of a power door lock feature. When a power door lock actuator fails, it disables the power door lock feature.

The most common complaint about a power door lock actuator is that it locks and unlocks intermittently. This may be due to a problem with the wiring or circuits.

Some symptoms of a faulty power door lock actuator are noises coming from inside the door. For example, when a motor is not turning, it will make a loud “clunk” sound. When a motor is working properly, there will be little or no noise.

A faulty power door lock actuator may also cause a car to lock and unlock randomly. This can happen due to a faulty circuit or circuits wearing out.

Alternatively, a faulty actuator may be the result of a water leak in the door. If this is the case, the water may enter the door lock actuator and cause it to malfunction. Fortunately, there are a number of ways to check the condition of your actuator and fix any problems.

Body controller

Almost all modern day cars have some form of power lock, but only a select few have a body controller to boot. The fancy name is the electronic control unit, but the acronym ECU stands for Electronic Control Unit, or ECU for short. The ECU is responsible for coordinating the myriad electronic components that are dotted throughout your vehicle’s occupant compartment. It also controls things like power windows and the air conditioning. You can see the ECU in action by glancing at your dashboard. It’s a small and power-packed box, but a discerning eye will spot a few stragglers amongst the more mundane tasks. The ECU is also responsible for ensuring the safety of passengers by ensuring that the doors remain unlocked until a specified interval.

The ECU’s lesser known cousins, like the power door lock, are only responsible for a few of the more mundane tasks. Aside from the usual suspects, the ECU also manages the power mirrors and the power windows, albeit on a less than optimal schedule. A faulty ECU isn’t quite as funky as it sounds, and can be rectified by a trip to the local mechanic. If you’re not a mechanic, you’ll likely be able to remedy the situation with a simple door lock replacement.

Check for broken wires

Occasionally, you will need to check for broken wires when using a power lock. Having a broken wire will require you to repair it, or replace it with a new one. However, this process can be quite difficult, as it is hard to reach the motor. If you are unsure what wires are connected to your vehicle, you should consult a wiring diagram. If you do not have a diagram, you can also use a multimeter to check for continuity across all wires. However, a multimeter is not enough to check for broken wires. You will also need rubber gloves to do this safely.

To check for broken wires, first make sure you have access to the wires that are in the lock motor. These are usually located near the plug on the door frame. If you can’t reach them, you can use jumper wires to connect the actuator to the 12 volt power supply and test it for power. If this does not work, you will need to remove the lock motor from its electronic control board and check for a broken wire harness. However, if this is not possible, you can use a Power Probe to apply 12 volts to the actuator.

editor by czh 2022-12-17